ALG has established a “five-in-one” quality management system, namely taking mutual benefits, product development, manufacturing process, after-sales service, and continuous improvement as a whole concept. Adhering to “zero defects, zero tolerance, and zero concession” in product quality, ALG keeps improving its process control capability.

By emphasizing quality management and high efficiency of systematic management, ALG keeps supplying stable high-quality products and services. We have established a “five-in-one” quality management system, namely assembling mutual benefits, product development, manufacturing process, after-sales service, and continuous improvement as a whole concept. Adhering to “zero defects, zero tolerance, and zero concession” in product quality, ALG keeps improving its process control capability.

Mutual Benefits. We implement dynamic management of suppliers, define supplier network based on the characteristics of raw materials they provide, adhere to mutual benefits and win-win basis to promote the positive development of supply chain.

Product Development. By establishing impeccable quality standards, we emphasize on the quality of product development and design, and have implemented quality control targets and the related measures during product development.

Manufacturing Process. We have implemented standardization work process. Through perfect production process and index result inspection mechanism, in combination with excellent performance management mode, we adhere to the quality management principles of combined responsibility, rights and benefits for related staff in terms of management, technology and production. Quality is always the core in every production process.

Continuous improvement. We implement dynamic and balanced management through a variety of improvement patterns, and constantly seek the opportunities for continuous improvement.

After-sales Service. We center on customers. In product design stage, we gain our advantages in product services with our deep understanding of user needs. ALG strives to offer professional, timely and warm after-sales service by constantly improving the customer response mechanism.

Continuous Improvement. By implementing dynamic and balanced management pattern, we keep improving through various ways with the participation of all staff.

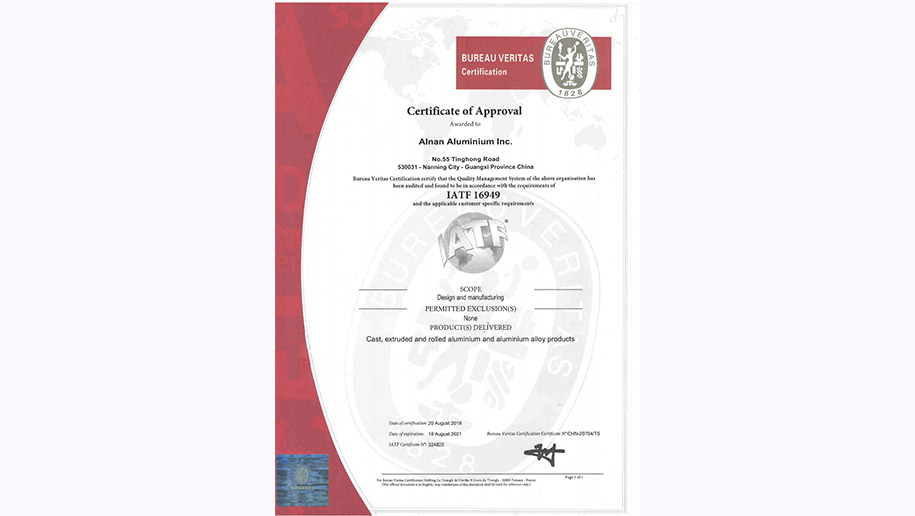

Through comprehensive quality control, we have established a scientific, rigorous and efficient quality management system. We have got 23 quality system certifications, including 3 basic system certifications, 9 industry system certifications, 3 special process certifications, and 7 third-party certifications, and 1 high performance certification, and thus gain the passport to enter high-end manufacturing fields such as aerospace, rail transportation, automobile and marine industries. In December 2018, we won the Chairman Quality Award for our outstanding quality management performance.